Component Introduction

Extrusion Machine

Based on Jinming's years of experience in extrusion system design, combined with the processing characteristics of materials and the principles of rheology, a continuous optimization design was developed through simulation to adapt to the processing of various different materials. The extruder was specifically optimized and precision processed for the processing of low crystalline point self-adhesive protective film materials, and has the characteristics of high output, low energy consumption, and good plasticization.

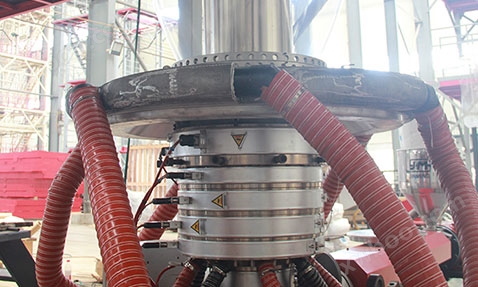

Die head

Based on Jinming's years of experience in die design, combined with the processing characteristics of materials and the principles of rheology, Jinming Company has manufactured various high-performance die heads through continuous technological innovation. At the same time, through simulation systems, it has optimized the design specifically for processing low crystalline point self-adhesive protective film materials, which helps to achieve perfect film thickness tolerances when processing different resins.

Type II winding machine

The winding device adopts a modular design and has multiple winding functions, which can adapt to the winding of materials with different characteristics, reduce tension fluctuations during winding, and provide high-quality winding. Equipped with automatic film cutting, automatic roll changing, automatic unwinding, automatic length counting, and fully automatic taper tension control, it can provide feedback based on the surface tension of the measured film and achieve automatic tracking, improving the flatness of the film winding. Effectively reducing the labor intensity of manual labor, reducing the amount of waste generated during manual coil replacement, improving work efficiency, and enhancing safety performance.